Printing Machine Vision Inspection Systems , Inline Color Control System

Product Details:

| Place of Origin: | China |

| Brand Name: | FOCUSIGHT |

| Certification: | ISO9001/CE |

| Model Number: | FS-SWAN |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Plywood |

| Delivery Time: | 60 Days |

| Supply Ability: | 20 Machines/Month |

|

Detail Information |

|||

| Inspection Speed: | 15000sheets/hour | Inspection Area: | 1040mmx720mm (customizable) |

|---|---|---|---|

| Paper Thickness: | 60~400g/m2 | Waste Handling: | Sound And Light Alarm |

| Highlight: | vision based inspection system,quality control vision systems |

||

Product Description

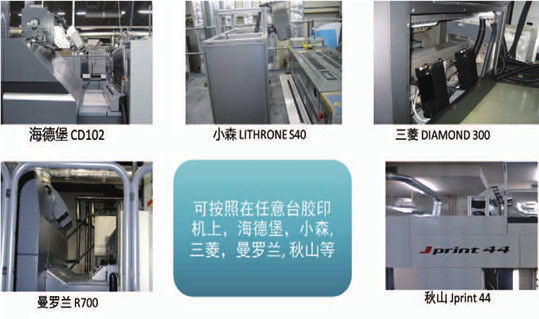

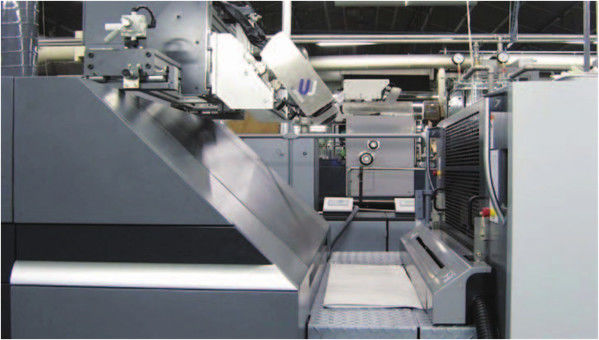

Inline Color Control System For Printing Machine

FS-SWAN – Swan Detection Series”

SWAN:Swan implies purity, loyalty and nobility.

New products combines advanced detection software (using cutting-edge algorithms and techniques, ensure accurate and high-speed workflow solutions, as well as the precise hardware platform integration and engineering implementation, create a first-class detection solution to meet the rapid growth of China offset printing market existing customers and new customer demand for defects detection.

Technical Specifications

- Inspection Speed - 15000sheets/hour

- Inspection Area - 1040mmx720mm (customizable)

- Paper Thickness - 60~400g/m2

- Paper Type - White cardboard, Bond Paper, Aluminized Paper, Laser Paper, etc

- Inspection resolution- 0.126mm x 0.126mm

- Precision Area - 0.1 mm or more squared (contrast≥30DN)

- Printing Defects Inspection - DarkWhite Spots, Mosquito marks, Drag Marks, Misregistration, color etc.

- Waste handling - Sound and light alarm

Advantages

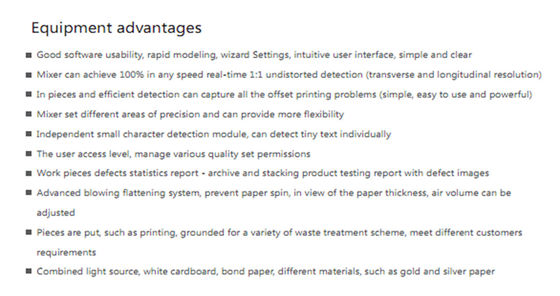

- Mixer can achieve 100% in any speed real-time 1:1 undistorted detection (transverse and longitudinal resolution)

- Good software usability, rapid modeling, wizard Settings, intuitive user interface, simple and clear

In pieces and efficient detection can capture all the offset printing problems (simple, easy to use and powerful)

In pieces and efficient detection can capture all the offset printing problems (simple, easy to use and powerful) Mixer set different areas of precision and can provide more flexibility

Mixer set different areas of precision and can provide more flexibility Independent small character detection module, can detect tiny text individually

Independent small character detection module, can detect tiny text individually The user access level, manage various quality set permissions

The user access level, manage various quality set permissions- Work pieces defects statistics report - archive and stacking product testing report with defect images

Advanced blowing flattening system, prevent paper spin, in view of the paper thickness, air volume can be adjusted

Advanced blowing flattening system, prevent paper spin, in view of the paper thickness, air volume can be adjusted Pieces are put, such as printing, grounded for a variety of waste treatment scheme, meet different customers requirements

Pieces are put, such as printing, grounded for a variety of waste treatment scheme, meet different customers requirements