Fabric Tags Inspection , 2 Tons Automatic Quality Control Vision Systems

Product Details:

| Place of Origin: | China |

| Brand Name: | FOCUSIGHT |

| Certification: | ISO9001/CE |

| Model Number: | FS-GECKO-200 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Plywood |

| Delivery Time: | 60 Days |

| Supply Ability: | 20 Machines/Month |

|

Detail Information |

|||

| Maximum Size: | 200mm × 300mm | Minimum Size: | 40mm × 70mm |

|---|---|---|---|

| Speed: | 150m/min | Power: | 10KW |

| Paper Weight: | 150 ~ 350 GSM | Machine Mechanical Size: | 3650mm (L) × 1000mm (W) × 1500mm (H) |

| Machine Weight: | 2Tons | ||

| Highlight: | quality control vision systems,quality control machine |

||

Product Description

Automatic High Speed Printing Inspection Machine for Fabric Tags, Gecko-200 Suitable for all types of Small Tags

Model Number:

FS-GECKO-200

Short Introduction:

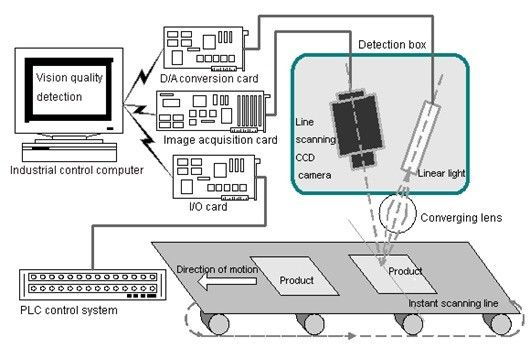

What: The Focusight Inspection Machine will precisely find out the defects of printing on cartons and reject the bad ones from the good ones automatically at high speed.

How: The Focusight cameras scan some good cartons as “STANDARD” and then while the rest of the printed jobs are inspected be scanned one by one and compared with the “STANDARD”, any mal-printed or defective ones will be rejected automatically by the system. It detects every type of printing or finishing Defects like Color Misregistration, Color variations, Hazing, Misprints, Defect in the text, spots, splashes, varnishing missing & Misregistration, embossing missing & Misregistration, Laminating problems, Die-cut problems, Barcode problems, Holographic foil, cure & cast and many other printing problems.

Technical Specification:

| Item | Parameter |

| Max. Transportation Speed | 200m / min |

| Max. Inspection Speed | 200m / min, about 60,000 pc / hour for tags 100mm length |

| Max. Sheet Dimension (W * L) | 200mm × 300mm |

| Min. Sheet Dimension (W*L) | 40mm×70mm |

| Thickness of sheet | 90~400 GSM |

| Total Mechanical Platform Dimension (L*W*H) | 6680mm×2820mm×1985mm |

| Total Weight | 2.5 Tons |

| Mechanical Platform Dimension (L*W*H) | 3650mm(L)* 2000 mm(W)* 1800(H)mm |

| At least 500mm personnel passageway shall be left around the equipment | |

| Equipment operating area (L*W*H) | 4000 mm(L)* 2200 mm(W)* 1900(H)mm |

| Total Net Weight | 2500kg |

| Power Supply | The entire equipment adopts 3 Phase 5 Line 380V/50/60HZ to supply power and it shall be grounded, with total power of 10KW |

| Air supply | Output working pressure should stable provide 6-8 bar. |

| Clean compressed air (should pass through oil-water separator) |

Service Support:

- The warranty of our machine is 12 months and service are available lifelong.

- Our expert will answer any inquiry within 24-48 hours, and it will be solved as soon as possible.

- We can send enough technicians to the Buyer’s company for installation and testing the machines.

- We supply the complete technical documents and the relative drawings of the electric components which were written in English.

- 24*7 Online Support

Payment & Delivery

- Package: Plywood Package.

- Payment: By 30 % T / T as deposit, 70% balance should be paid 10 days before shipment. Or 100 %L/C at sight.

- Delivery: 60 days after we get the down payment.

FAQs

Q: What its principle of this machine? Is this offline or online?

A: It takes few good cartons as standard, scans it using High Resolution CCD cameras, creates the template and inspects the other cartons for good and defected ones. The machine is offline type.

Q: What is the maximum speed of the machine?

A: 250 meters / min (Can vary depending on the job size)

Q: Do you have a Double Sheet sensor? If double sheet comes between the production what will happen?

A: Yes, it has Ultrasonic Double Sheet detector. If double sheets detect by sensor during production both cartons will be rejected.

Q: Can we adjust the tolerance level in different regions of the carton to enable differentiation between critical & Non-critical parameters?

A: Yes, we can adjust the tolerance level for every regions of the cartons depending upon QC requirements.

Q: Can we generate a Defect report (MIS REPORT) that can be downloaded to a USB for each job?

A: Yes, we can have a summary Defect report for every job with defect images and other details.

Pictures at Glance:

![]()

![]()

![]()