15.1KW Machine Vision Inspection Systems , Offset Inline Quality Inspection System

Product Details:

| Place of Origin: | China |

| Brand Name: | FOCUSIGHT |

| Certification: | ISO9001/CE |

| Model Number: | FS-SHARK-650-M/ FS-SHARK-650 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Plywood |

| Delivery Time: | 60 days |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 20 Per Month |

|

Detail Information |

|||

| Detection Area: | 650mm | Mechanical Weight: | 4 Ton |

|---|---|---|---|

| Name: | Printing Quality Image Detection System V2.0 | Model: | FS650shark |

| Highlight: | high speed vision inspection systems,vision based inspection system |

||

Product Description

Offset Inline Inspection System

TECHNICAL SPECIFICATION

FS-650-Shark-P3A1N1

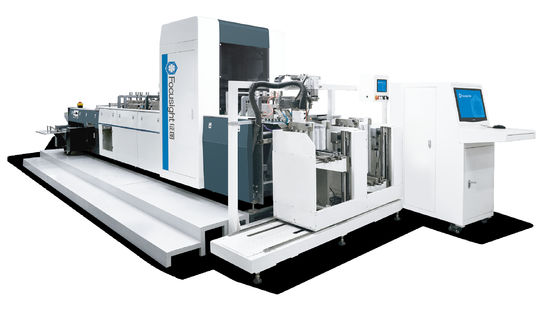

1) Device appearance

|

FS-SHARK-650 Carton Transport Platform |

| Product Name | Product Model | Paper Type |

| Printing Quality Image Detection System V2.0 | FS650shark | Gold, Silver & White Card |

2) Machine Configuration, Functions & Parameters

2.1Acceptance of product types

| Type | Classification of accepted product type | Description |

| Color box | 3 | Gold, Silver & White Card |

- Machine Configuration:

| Project Name | Configuration Instruction | No. | Functions Description | |

| The Department of Detection & Measurement distribution series | Front printing variable code detection station | Exclusive German Imported color C4K CCD camera | 1 |

|

| Imported optical imaging lens | 1 | |||

| Dedicated dome light source, length 525mm. | 1 | |||

| High-speed image processing computer workstation (including high-speed image acquisition and processing card) | 1 | |||

| Positive Pressing Varnish Inspection Station | Imported from England E2V high-speed 8K pixel line scan camera | 1 |

|

|

| Imported optical imaging lens | 1 | |||

| Dedicated oblique light source, the length of 525mm | 1 | |||

| High-speed image processing computer workstation (including high-speed image acquisition and processing card) | 1 | |||

|

Positive film embossing detection station |

Imported from England E2V high-speed 8K pixel line scan camera | 1 |

|

|

| Imported optical imaging lens | 1 | |||

| Dedicated reflective light source, the length of 570mm | 1 | |||

| High-speed image processing computer workstation (including high-speed image acquisition and processing card) | 1 | |||

|

Reverse detection station |

Imported high-speed full-color 4kCCD camera | 1 |

|

|

| Imported optical imaging lens | 1 | |||

| Special light source, length of 525mm. | 1 | |||

| High-speed image processing computer workstation (including high-speed image acquisition and processing card) | 1 | |||

|

Surface array |

Face array camera and lens | 1 |

|

|

|

Special surface array light source |

1 | |||

| Detect software configuration | Print Inspection Module for Visual Inspection Software FSCheck V2.0 | 1 | ||

| Two - dimensional code detection module | 1 | Detection of re-code, error code, missing code | ||

|

Defect Detection Statistical Report |

1 | The defects can be detected in the statistical type, data and other information | ||

| Detection equipment | Dedicated printing detecting dust sealed cabinet | 1 | Protection of detection devices from dust | |

| Industrial refrigeration and air conditioning | 2 | Protection of detection devices from process heat | ||

| 22 inch LCD monitor and keyboard and mouse | 1 | |||

| Sound and light alarm device | 1 | Sound and light alarm when Error occurs | ||

| Mechanical platform configuration | Mechanical transmission platform structure configuration | Friction feeder | 1 | |

| Suction Feeder | 1 | |||

| Mix Feeder | 1 | |||

| Note: film and water-based varnish and other easy to scratch the sample is not within the scope of friction technology | ||||

| Air blower | 1 | Remove paper wool, to avoid false inspection | ||

| Goods delivery structure | 1 |

RFish Scale ☐Vertical paper pick-up |

||

| Waste Collection Unit | 1 | |||

| High-speed pneumatic reject mechanism | 1 | |||

| Rear Monitor | 1 | |||

| Electrical supporting system | 1 | Standardize operation | ||

| Strong electric part of the mechanical platform | Germany SEW main motor | 1 | 4KW supply main drive power | |

| Germany SEW paper feed motor | 1 | 1.5KW supply feeding transmission power | ||

| Air pump | 1 | 2 sets of 4KW | ||

| Delivery Unit motor | 1 | 0.4KW | ||

| Rejection Unit motor | 1 | 0.4KW | ||

| Vibration motor | 1 | 0.04KW | ||

Note 1: The transmission system requires the user to provide the factory centralized gas source or external air compressor for the equipment to remove the waste.

- Device function parameters

| Project | Function Parameter | |

| Maximum detention speed | 220 m / min; 180 m / min | |

| Maximum paper size | Friction Feed | 650mm (width) * 450mm (length) |

| Suction Feed | 650mm (width) * 450mm (length) | |

|

Minimum paper size |

Friction Feed | 90mm (width) * 90mm (length) |

| Suction Feed | 105mm (width) * 150mm (length) | |

| Paper adaptability | 120~700g/㎡; | |

| Detection Area | 650mm | |

| Max Detection accuracy (mm) | Positive front station: 0.158mm * 0.12mm (4K camera) Front oblique station: 0.079mm * 0.12mm (8K camera) Front Reflector: 0.079mm * 0.12mm (8K camera) 220m / min Surface array position: 0.067mm * 0.067mm Front Reflector: 0.16mm * 0.24mm (4K camera) |

|

| Min Detection accuracy (mm) | Positive front station: 0.158mm * 0.1mm (4K camera) Front oblique station: 0.079mm * 0.1mm (8K camera) Front Reflector: 0.079mm * 0.1mm (8K camera) 180m / min Surface array position: 0.067mm * 0.067mm Front Reflector: 0.16mm * 0.2mm (4K camera) |

|

| Conventional defect detection (when defect contrast is greater than 40) |

|

|

| Variable information detection |

|

|

Supports single and double line, alphanumeric or alphanumeric characters; (Face array imaging one-dimensional code, two-dimensional code, characters, the need to 80mm * 60mm range) |

||

| Cabinet Size | 1440mm × 800mm × 600mm (L * W * H) standard | |

| Machine Size | 6950mm × 3650mm × 2200mm (L * W * H) | |

| Mechanical Weight | 4 Tons | |

| Total power | 15.1KW | |

3) Toolbox configuration list

Remarks:

4) Installation requirements

Ø Unloading the first car or forklift with the equipment from the truck unloaded, and then open the wooden box, be careful not to damage the shell;

Ø Equipment can be placed when the overall forklift truck, forklift force as shown below:

- When handling the whole, please use 3 tons and 3 tons or more forklift;

- When the parts are disintegrated, please use at least 2 tons and more than 2 tons forklift:

- machine placed as follows:

- equipment at least 500mm staff around the channel;

- Centralized air supply or external air compressor, trachea diameter of at least 12mm, the output stability> 0.8Mpa pressure, 400mm width, 300g / ㎡ above the kit to kill the waste output stability> 1Mpa pressure;

- Machine with 3-phase 5-wire 380V / 50 / 60HZ power supply, the machine needs to ground, the total power 15KW;

- Line requirements: greater than or equal to 10 square millimeters copper core cable.

- Use greater than or equal to 60 A circuit breaker, the inverter has a high harmonic, without the use of secondary protection.