Phone Box Packaging Inline Inspection System With Fully Suction Platform

Product Details:

| Place of Origin: | China |

| Brand Name: | FOCUSIGHT |

| Certification: | ISO9001/CE |

| Model Number: | FS-GECKO-500 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Plywood |

| Delivery Time: | 60 Days |

| Supply Ability: | 20 Machines/Month |

|

Detail Information |

|||

| Maximum Paper Size: | 480mm(Width)* 420mm(Length) | Minimum Paper Size: | 90mm(Width)* 90mm(Length) |

|---|---|---|---|

| Adapt To Paper Weight: | 90~350g/㎡(paper Weight > 195g) | Application: | Phone Box Packaging |

| Highlight: | industrial vision system,vision inspection equipment |

||

Product Description

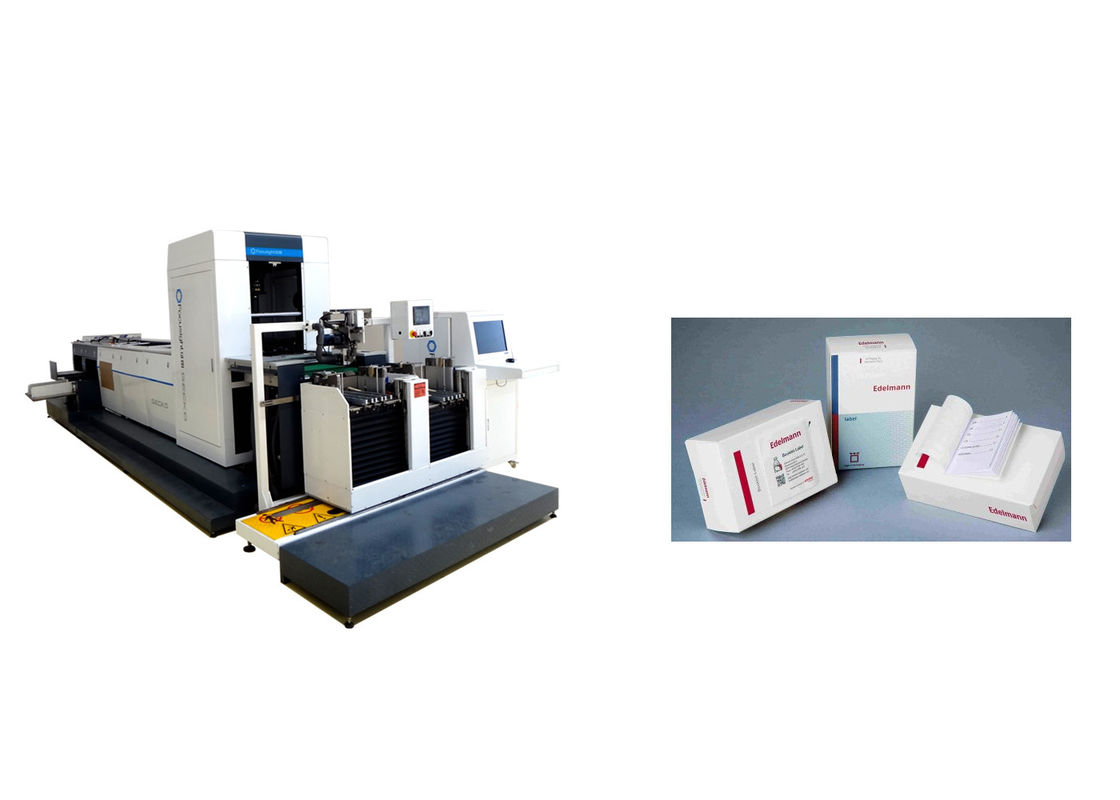

500mm Size Phone Box Packaging Inline Inspection System with Fully Suction Platform

MODEL - FS-GECKO-500

Product Description

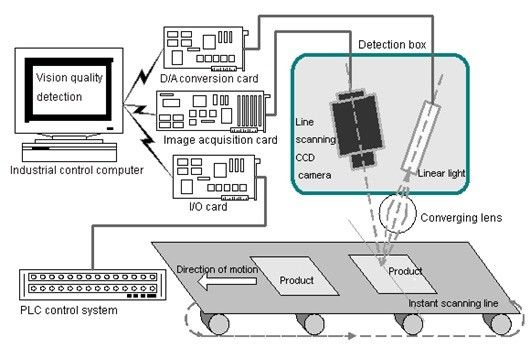

What: The Focusight Inspection Machine will precisely find out the defects of printing on presswork and reject the bad ones from the good ones automatically.

How: The Focusight cameras scan some good presswork as “STANDARD” and then while the rest of the printed jobs are inspected be scanned one by one and compared with the “STANDARD”, any mal-printed or defective ones will be rejected automatically by the system. It detects every type of printing or finishing fault – color misregistration, color variations, hazing, misprints, defect in the text, spots, splashes, varnishing missing& misregistration, embossment missing& misregistration, laminating problems, die-cut problems, barcode problems,

Holographic Stripe, cure& cast and many other printing problems.

Technical Data

| Project | Function parameters | |

| Maximum detection speed | 220m/min 180m/min | |

| Field of view | 500mm | |

| Maximum paper size | Friction Feeder | 480mm(Width)* 420mm(Length) |

| Suction Feeder | 480mm(Width)* 420mm(Length) | |

| Minimum paper size | Friction Feeder | 90mm(Width)* 90mm(Length) |

| Suction Feeder | 90mm(Width)* 120mm(Length) | |

| Adapt to paper weight | 90~350g/㎡(paper weight > 195g) | |

| Imaging accuracy (mm) |

Direct Station Image Accuracy:0.12mm*0.12mm(4KCamera) Oblique Station Image Accuracy :0.06mm*0.12mm(8KCamera) Reflection Station image Accuracy:0.06mm*0.12mm(8KCamera) 220m/min Reverse Station Image Accuracy:0.13mm*0.24mm(4KCamera) Array Image Accuracy :0.067mm*0.067mm |

|

| Image Accuracy (mm) |

Direct Station Image Accuracy:0.12mm*0.12mm(4KCamera) Oblique Station Image Accuracy :0.06mm*0.12mm(8KCamera) Reflection Station image Accuracy:0.06mm*0.12mm(8KCamera) 180m/min Reverse Station Image Accuracy:0.13mm*0.24mm(4KCamera) Array Image Accuracy :0.067mm*0.067mm |

|

| (Defect contrast of 40) defect detection routine |

|

|

| Bar Code Detection |

|

|

| Variable code detection (face array) |

Supports single and double line, alphanumeric or alphanumeric characters; |

|

0% Chance for Defected Cartons

- High-grade printing Quality control for all types soft, easily scratch able folding cartons/cosmetics packaging/luxury boxes/phone box etc.

- Up to three top cameras, one reverse side camera and area cameras

- The unique lighting system enables the inspection of even highly reflective substrates

- Focusight inspection machine allows you to offer your customers quality assurance for packaging products with high added value such as luxury goods and pharmaceuticals.

- Focusight combines LED lighting technology and 4K or 8K camera system with high-performance data processing and image analysis software,

- This technology checks the quality of carton blanks at a speed of up to 250 m/min.

- It gives you reliable control of finishes such as hot foil application, holograms, embossings or coating patterns.

Object of Inspection (the kind of Detectable defects on Cartons)

| DEFECT TYPE | CAMERA TYPES | |||

| COLOUR CAMERA | ANGLE CAMERA | SURFACE CAMERA | REVERSE CAMERA | |

| PRINT MISS | ★ | △ | △ | △ |

| DIE- CUT OUT | ☆ | ★ | △ | △ |

| MIS-REGISTRATIONS | ★ | △ | △ | △ |

| DARK SHADE | ★ | △ | △ | △ |

| LIGHT SHADE | ★ | △ | △ | △ |

| SHADE VARIATION | ★ | △ | △ | △ |

| INK SCUM | ★ | △ | △ | △ |

| DIRTY | ★ | △ | ☆ | △ |

| WATER DRIPS | ★ | △ | ☆ | △ |

| SMEARS | ★ | △ | △ | △ |

| BARCODE | ★ | △ | △ | △ |

| SET OFF | ★ | △ | △ | △ |

| HICKEYS | ★ | △ | △ | △ |

| SMUDGY PRINTING | ★ | △ | △ | △ |

| PRINITING WASTE | ★ | △ | △ | △ |

| SCRATCHES | ☆ | ★ | ☆ | △ |

| INK SCRATCHES | ★ | △ | △ | △ |

| FOIL MISS / OUT | ☆ | ★ | ☆ | △ |

| BRAILLE MISS / OUT | △ | ★ | △ | △ |

| EMBOSSING MISS / OUT | △ | ★ | ☆ | △ |

| LAMINATION DEFECT | △ | ☆ | ★ | △ |

| IMPROPER VARNISH | △ | △ | ★ | △ |

| UV TEXTURE | △ | ☆ | ★ | △ |

| WRINKLE DEFECT | △ | ☆ | ★ | △ |

| FINGER MARK | △ | △ | ★ | △ |

| HOLOGRAM FOIL DEFECT | ☆ | ☆ | ★ | △ |

| REVERSE SIDE TEXT DEFECT | △ | △ | △ | ★ |

| DUST OR INSECTS | △ | △ | △ | ★ |

| CREASING LINE REVERSE SIDE | △ | △ | △ | ★ |

| SCRATCHES IN BACKSIDE | △ | △ | △ | ★ |

| REVERSE SIDE DIRT MARKS | △ | △ | △ | ★ |

| Among them: ★ can be checked, ☆ partially can be checked, △ can’t be checked | ||||