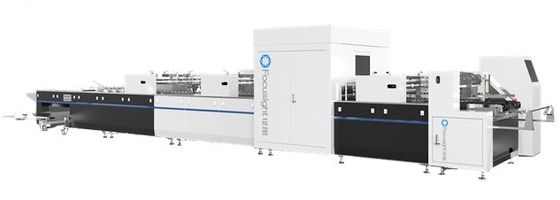

28KW Visual Inspection Equipment For Printed Corrugated Boxes Quality Control

Product Details:

| Place of Origin: | China |

| Brand Name: | FOCUSIGHT |

| Certification: | ISO9001/CE |

| Model Number: | FS-SHARK-1100 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Plywood |

| Delivery Time: | 60 Days |

| Supply Ability: | 20 Machines/Month |

|

Detail Information |

|||

| Paper Type/gsm: | 200~650 G/m2 | Max. Speed: | 220m/min |

|---|---|---|---|

| Max. Sheet Size: | 1100mm * 900mm | Min. Sheet Size: | 400mm * 300mm |

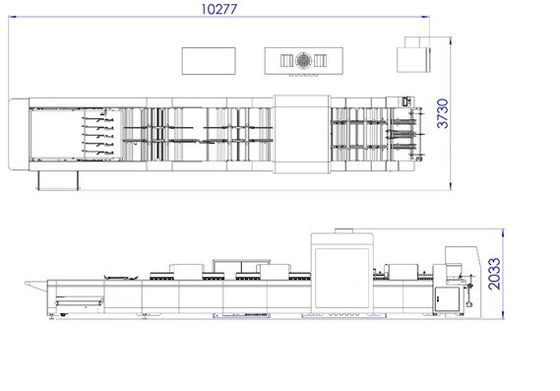

| Corrugated Weight: | B,E,F Type | Mechanical Platform Dimension: | 9500mm*3300mm*2000mm |

| Total Power: | 28KW | Total Weight: | 8 Tons |

| Highlight: | automatic visual inspection machine,auto visual inspection machine |

||

Product Description

Focusight Visual Inspection Equipment for Printed Corrugated Boxes Quality Control

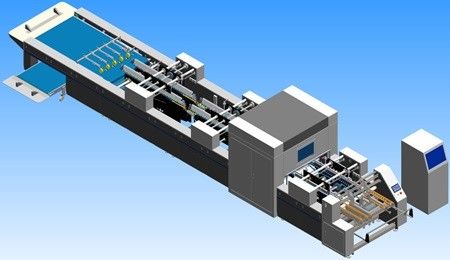

MODEL - BIG SHEET HIGH SPEED QUALITY INSPECTION MACHINE FS-SHARK-N1100

Technical Data

| FS-SHARK-N1100 | |

| Paper Type/gsm | 200~650 g/m2 |

| Max. speed | 220m/min |

| Max. sheet size | 1100mm * 900mm |

| Min. sheet size | 400mm * 300mm |

| Corrugated Weight | B,E,F Type |

| Mechanical Platform Dimension | 9500mm*3300mm*2000mm |

| Total Power | 28kw |

| Total Weight | 8 Tons |

Performance Parameters of Inspection System

| Product Type | FS-SHARK-N1100-P2N1 |

| Inspection FOV | 1100mm (Width) |

| Imaging Resolution (mm) |

Front Imaging Resolution(Regular Printing Side): 0.15mm*0.12mm (7k color camera) Front Imaging Resolution(Laminating, Varnishing & Embossing Side): 0.137mm*0.12mm (8k w/b camera) Back side Imaging Resolution(Laminating, Varnishing & Embossing Side): 0.137mm*0.12mm (8k w/b camera) |

| Regular Printing (when the defect contrast is over grade 40) |

1. Minimum Inspection Area of Regular Defects, such as Printing Missing, Dirty Spot and stuff like that: ≥0.3 mm2 2. Minimum Inspection Area of Foil Stamping Defects:≥0.3mm2 3. Print Misregistration Inspection: ≥0.2mm 4. Die Cutting Misregistration Inspection: ≥0.2mm 5. Blade Streak: vertical stripes with width over 0.1mm, and contrast over grade 40 are detectable 6. Local Color Difference Inspection ΔE≥3 |

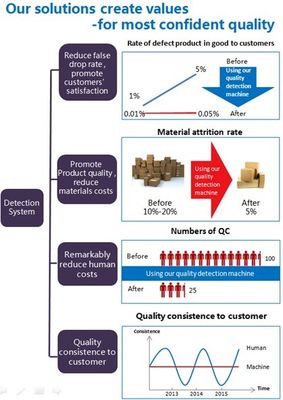

0% Chance for Defected Cartons

- High-grade printing Quality control for all types of big cartons;

- Up to three top cameras, one reverse side camera and area cameras

- The unique lighting system enables the inspection of even highly reflective substrates

- Focusight inspection machine allows you to offer your customers quality assurance for packaging products with high added value such as luxury goods and pharmaceuticals.

- Focusight combines LED lighting technology and 4K or 8K camera system with high-performance data processing and image analysis software,

- This technology checks the quality of carton blanks at a speed of up to 250 m/min.

- It gives you reliable control of finishes such as hot foil application, holograms, embossings or coating patterns.

Focusight Overseas Exhibition:

![]()

![]()