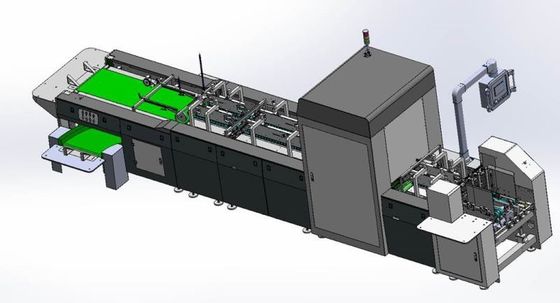

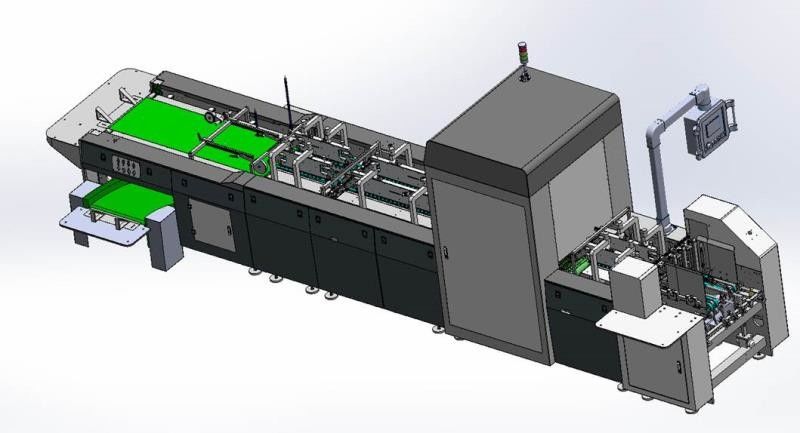

Medicine Box Printing Quality Control Equipment With Auto Stacking System

Product Details:

| Place of Origin: | China |

| Brand Name: | FOCUSIGHT |

| Certification: | ISO9001/CE |

| Model Number: | FS-SHARK-500 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Plywood |

| Delivery Time: | 60 Days |

| Payment Terms: | L / C , T / T |

| Supply Ability: | 20 Per Month |

|

Detail Information |

|||

| Maximum Size: | 480mm × 420mm | Minimum Size: | 90mm × 90mm |

|---|---|---|---|

| Speed: | 250m/min | Power: | 12KW |

| Paper Weight: | 90 ~ 400 GSM | Machine Mechanical Size: | 6680mm (L) × 2820mm (W) × 1985mm (H) |

| Machine Weight: | 3.5Tons | ||

| Highlight: | industrial vision system,printing inspection machine |

||

Product Description

High Speed Min 90mm & Max 500mm Size Medicine Box Printing Quality Vision Systems

FS-SHARK-500-Printing Quality Inspection SYSTEM

PRODUCT FEATURES AT GLANCE:

- Two types of feeder for various package stocks.

- Standard friction feeder-for a regular paper surface, and high speed inspection this feeder is a standard option.

- Suction feeder-To avoid scratch marks on the sensitive cartons you can use suction feeder.

- Inspection Unit

- Assembled the line scan colour camera from Chromasens Germany. The highest line rate in the world.

- Cameras in multi-station with specific lighting source with own patent.

- Vacuum under belt to flatten the cartons.

- Assembled with Industrial air condition to guarantee the suitable temperature for cameras.

- Conveyor Unit- Two belts to clamp the cartons to make it stable and high-speed.

- Twin Rejection (Air & Plate) – The twin rejection means the machine have two (Air and Plate) type of rejections. We can choose the rejection depending upon the carton thickness. Air rejecter can be used for 90gsm to 400gsm and Plate Rejecter is for 100gsm to 700gsm & irregular shapes cartons.

- Rejection Unit – Machine have separate platform for rejected cartons and have mechanism to count the delivered cartons.

- Collection Unit / Delivery Unit-The platform for good one and it is easy to collect with auto counting of quantity collected. Also, have batch collection for good cartons.

- Automatic – Stacking system-For automatically collection of cartons at the end of the machine which is suitable for regular shape cartons.

SEE WHAT THE FS-SHARK-500 CAN DO

Technical Specifications

| Item | Parameter FS-SHARK 500 |

| Max. Transportation Speed | 250m / min |

| Max. Inspection Speed | 250m / min |

| Max. Sheet Dimension (W * L) | 480mm × 420mm |

| Min. Sheet Dimension (W * L) | 90mm × 90mm |

| Thickness of sheet | 90 ~ 400 GSM |

| Total Mechanical Platform Dimension (L * W * H) | 6680mm × 2820mm × 1985mm |

| Total Weight | 3.5 Tons |

IMAGING PRECISION

| Front Imaging Resolution (Colour Camera) | 0.11X0.12mm |

| Front Imaging Resolution (Angle Camera) |

|

| Front Imaging Resolution (Surface Camera) |

|

| Reverse Imaging Resolution (Reverse Camera) |

|

DEFECT DETECTION

| Minimum defect size (as a point) | 0.10mm 2 (Contrast > 20DN) |

| Minimum defect size (as a line) | 0.1mm X 5mm (Contrast > 20DN) |

| Minimum detection area of hot stamping |

|

| Print Mis-Registration detection | ± 0.10mm |

| Die-cutting deviation detection | ± 0.10mm (Contrast > 20DN) |

| Local colour difference detection |

|

| Barcode detection | Reading frame, error code, repeated code |

| Characters detection | Wrong word, leak word, corresponding to bar code |

| Appearance detection | Spot, broken line, white & black bracing wire, ink leak, warp, skew |

| Two dimensional code detection | Two dimensional code recognition |

FAQS

Q: What its principle of this machine? Is this offline or online?

A: It takes few good cartons as standard, scans it using High Resolution CCD cameras, creates the template and inspects the other cartons for good and defected ones. The machine is offline type.

Q: How do you control your machine? Through PLC or PCB?

A: Both, PLC to control the machine and PCB to control the inspection system.

Q: What kind of feeder it has, belt driven or suction?

A: Both (optional), Suction feeder is suitable for irregular shape cartons and avoids scratches on its surface, recommended for cosmetic cartons

.

Q: In case of belt feeder does it has a vibrator system?

A: Yes, it has a vibrator system.

Q: What is the maximum speed of the machine?

A: 250 meters / min (Can vary depending on the job size)

Q: What is the average production speed?

A: Average production can be around 250 meter / min subject to continuous feeding.

Q: What is the approx. make-ready time?

A: Within 20-25 minutes for any new job which includes:

- Feeder setting

- Model making

- Tolerance setting

- Test run

For repeat jobs we can extract the previously created model settings and hence it saves the time.

Q: How do you ensure the carton’s flatness during inspection in high speed?

A: We using 2 strong suction pumps down the camera to flat the carton for inspection in high speed.

Q: Do you have a Double Sheet Detector?

A: Yes, It has Ultrasonic Double Sheet detector.

Q: How many operators this machine require? Do they need any specializations?

A: Normally two person are enough to control the machine. They should have a good mechanical knowledge and basic printing knowledge at least.

Q: Can we separate good and bad products in batches?

A: Yes, we can separate good and bad products in specific quantity batches and Optional Stacker can make the piles of all the lots, recommended for cigarette industry.

Q: How many cameras this machine have and what’s their role?

A: Total 4 Cameras

1 st Top Camera: E2V 8K Monochrome Reflection Type camera for checking UV Coating, Lamination, Scratch, Bubble, Wrinkle, Varnishing and Missing defects.

2 nd Top Camera: E2V 8K Monochrome Angle Type camera for checking

Embossing, Foil Stamping, Creasing and Braille.

3 rd Top Camera: C4 4K Colour RGB camera for checking all type of printing defects including Die-cut error, Text defects, Unwanted spots, Colour Misregistration & Variation up to △ E <3, Variable Barcode and QR Code.

4 th Bottom Camera: V3 4K Monochrome camera for bottom side defects like dead insects marks, dirt marks and stains.