Focusight Floral Stereoscopic Warehouse Management System

Product Details:

Get Best Price Contact Now|

Detail Information |

Product Description

Focusight Floral Stereoscopic Warehouse Management System

This is the world's first fully intelligent, end-to-end system for boxed flower warehousing, distribution, and high-efficiency logistics.

The system primarily consists of:

- A multi-channel inbound system for boxed flowers,

- A multi-channel outbound system,

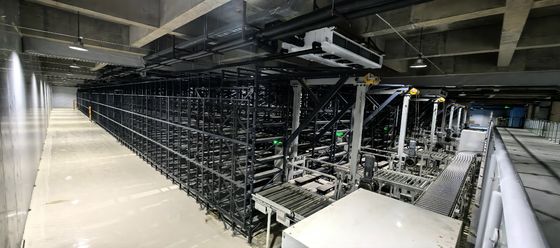

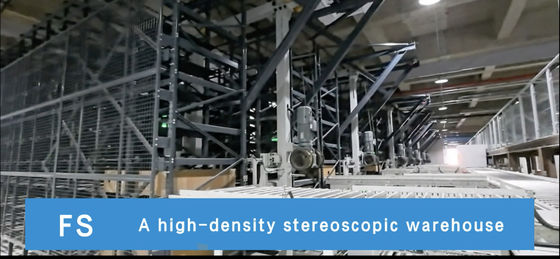

- A high-density stereoscopic warehouse,

- Intelligent conveying lines, and

- Robotic grasping systems.

It achieves efficient inbound processing, high-density storage, multi-channel outbound operations, and full-process automation for boxed flowers, significantly reducing labor costs.

Multi-channel Inbound System

- Interfaces with the customer's post-harvest boxed flower workshop

- Boxes feature QR codes on all four sides

- Supports multiple box specifications:

Length: 1010–1030 mm

Width: 440–460 mm

Height: ≤250 mm

- High inbound efficiency

- Single-channel capacity: 100 boxes/hour

- 8-channel total capacity: ~800 boxes/hour

- Each box contains ~120 fresh-cut flower stems

- Total stem processing: 96,000 stems/hour

Intelligent Conveying System

- Interfaces with the inbound system, 3D storage, and outbound system

- Features real-time monitoring to pinpoint the exact location of every flower box

- Ensures flexible routing and traceability, enabling high-throughput streamlined operations

Stereoscopic Warehouse

Focusight possesses mature implementation experience and has successfully served multiple industries such as printing and packaging. For instance, AGVs place finished cartons onto standard pallets, while the system automatically generates barcodes. Guided by WMS instructions, robots precisely store pallets on 11-meter-high racks, increasing space utilization by 60%. During outbound operations, RFID scanning enables the system to automatically plan optimal paths, achieving efficient handling of 50 pallets per hour. With pallet positioning accuracy of ±1 mm, the system meets clients' precision requirements.

The WMS system serves as the central brain. Through its interface, it monitors the status of over 2,000 storage locations in real time. When new pallets arrive, the algorithm automatically allocates optimal locations within 0.5 seconds based on 12 parameters including dimensions, expiration dates, and outbound frequency. Its dynamic path planning functionality boosts efficiency by 40%, ensuring urgent orders are dispatched promptly.

**Robotic Arms**

Achieve high-speed operation. Featuring a dual-arm configuration enabling parallel grasping of at least two items simultaneously. Capable of accessing any point within the workspace upon command, significantly saving aisle space, reducing costs, and boosting efficiency.

**Outbound Dock**

Supports 5-10 customizable ports. Enables flexible port allocation for VIP clients, with multiple ports accommodating diverse customer requirements.

**MES Central Management System**

The MES interfaces with client ERP systems to enable end-to-end traceability from order to labeling. Upon receiving ERP orders, MES automatically retrieves data, drives label printers to generate unique QR codes. Post-label scanning triggers WMS synchronization. During outbound, QR code scanning reveals complete product data—meeting the "single-code traceability per item" requirement. Real-time warehouse visualization via large screens supports mobile/PAD monitoring.