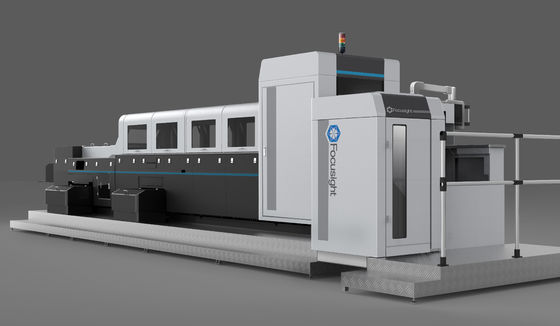

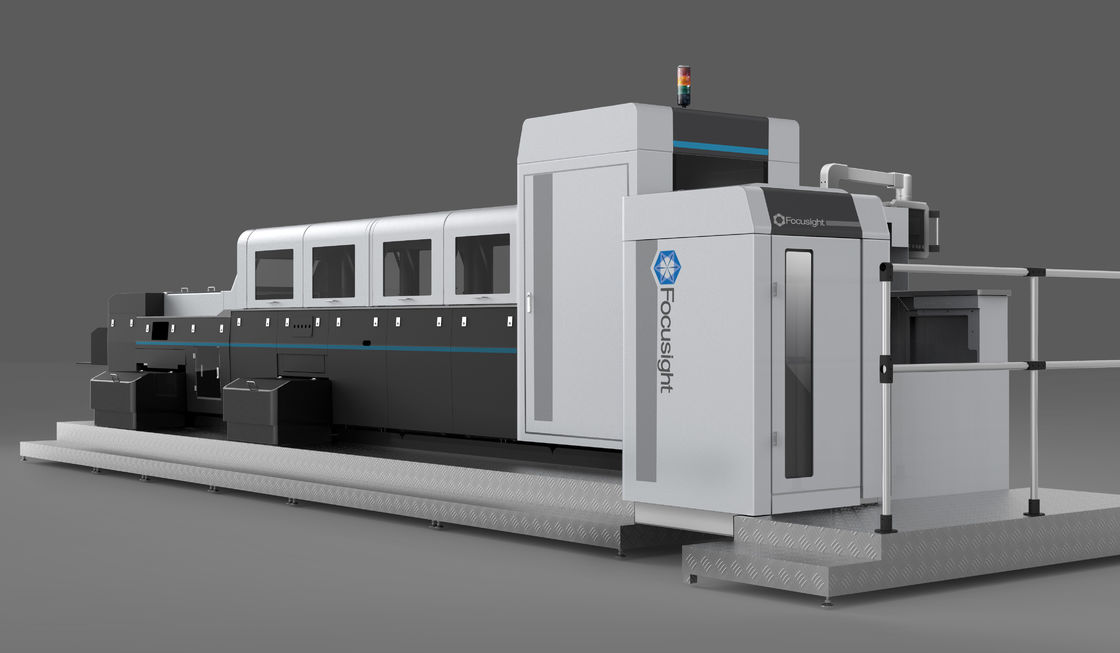

Auto Quality Inspection Machine For E Cigarette Packaging Defects Detection

Product Details:

| Place of Origin: | China |

| Brand Name: | FOCUSIGHT |

| Certification: | ISO9001/CE |

| Model Number: | FS-SHARK-500 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Plywood |

| Delivery Time: | 60 Days |

| Payment Terms: | L / C , T / T |

| Supply Ability: | 20 Per Month |

|

Detail Information |

|||

| Maximum Size: | 480mm × 420mm | Minimum Size: | 90mm × 90mm |

|---|---|---|---|

| Speed: | 250m/min | Power: | 12KW |

| Paper Weight: | 90 ~ 400 GSM | Machine Mechanical Size: | 6680mm (L) × 2820mm (W) × 1985mm (H) |

| Machine Weight: | 3.5Tons | ||

| Highlight: | quality inspection system,industrial inspection equipment |

||

Product Description

Focusight Automatic E-Cigarette Packaging Quality Inspection Machine

MODEL-FS-SHARK 500 - Printing Quality Inspection Machine

0% Chance for Defected Cartons

- High-grade printing Quality control for all types folding cartons / pharmceuticals packaging / color boxes / tags / labels / cigarette blanks / surface defects etc.

- Up to three top cameras, one reverse side camera and area cameras

- The unique lighting system enables the inspection of even highly reflective substrates

- Focusight inspection machine allows you to offer your customers quality assurance for packaging products with high added value such as luxury goods and pharmaceuticals.

- Focusight combines LED lighting technology and 4K or 8K camera system with high-performance data processing and image analysis software,

- This technology checks the quality of carton blanks at a speed of up to 250 m / min.

- It gives you reliable control of finishes such as hot foil application, holograms, embossings or coating patterns.

Technical Data

| Specifications | FS-SHARK-500 |

| Paper Type / GSM | 90 ~ 400 GSM |

| Max. Speed | 250m / min |

| Max. Output | 80,000 s / h-100,000 s / h |

| Max. Sheet size | 480mm × 420mm |

| Min. Sheet size | 90mm × 90mm |

DEFECT DETECTION

| Defect Type | Detection |

| Minimum defect size (as a point) | 0.10mm 2 (Contrast > 20DN) |

| Minimum defect size (as a line) | 0.1mm X 5mm (Contrast > 20DN) |

| Minimum detection area of hot stamping | 0.10mm 2 |

| Print Mis-Registration detection | ± 0.10mm |

| Die-cutting deviation detection | ± 0.10mm (Contrast > 20DN) |

| Local color difference detection | E > 3 |

| Barcode detection | Reading frame, error code, repeated code |

| Characters detection | Wrong word, leak word, corresponding to bar code |

| Appearance detection | Spot, broken line, white & black bracing wire, ink leak, warp, skew |

| Two dimensional code detection | Two dimensional code recognition |

Object of Inspection (the kind of Detectable defects on Cartons)

| DEFECT TYPE | CAMERA TYPES | |||

| COLOUR CAMERA | ANGLE CAMERA | SURFACE CAMERA | REVERSE CAMERA | |

| PRINT MISS | ★ | △ | △ | △ |

| DIE- CUT OUT | ☆ | ★ | △ | △ |

| MIS-REGISTRATIONS | ★ | △ | △ | △ |

| DARK SHADE | ★ | △ | △ | △ |

| LIGHT SHADE | ★ | △ | △ | △ |

| SHADE VARIATION | ★ | △ | △ | △ |

| INK SCUM | ★ | △ | △ | △ |

| DIRTY | ★ | △ | ☆ | △ |

| WATER DRIPS | ★ | △ | ☆ | △ |

| SMEARS | ★ | △ | △ | △ |

| BARCODE | ★ | △ | △ | △ |

| SET OFF | ★ | △ | △ | △ |

| HICKEYS | ★ | △ | △ | △ |

| SMUDGY PRINTING | ★ | △ | △ | △ |

| PRINITING WASTE | ★ | △ | △ | △ |

| SCRATCHES | ☆ | ★ | ☆ | △ |

| INK SCRATCHES | ★ | △ | △ | △ |

| FOIL MISS / OUT | ☆ | ★ | ☆ | △ |

| BRAILLE MISS / OUT | △ | ★ | △ | △ |

| EMBOSSING MISS / OUT | △ | ★ | ☆ | △ |

| LAMINATION DEFECT | △ | ☆ | ★ | △ |

| IMPROPER VARNISH | △ | △ | ★ | △ |

| UV TEXTURE | △ | ☆ | ★ | △ |

| WRINKLE DEFECT | △ | ☆ | ★ | △ |

| FINGER MARK | △ | △ | ★ | △ |

| HOLOGRAM FOIL DEFECT | ☆ | ☆ | ★ | △ |

| REVERSE SIDE TEXT DEFECT | △ | △ | △ | ★ |

| DUST OR INSECTS | △ | △ | △ | ★ |

| CREASING LINE REVERSE SIDE | △ | △ | △ | ★ |

| SCRATCHES IN BACKSIDE | △ | △ | △ | ★ |

| REVERSE SIDE DIRT MARKS | △ | △ | △ | ★ |

| Among them: ★ can be checked, ☆ partially can be checked, △ can't be checked | ||||

FAQs

Q: What its principle of this machine? Is this offline or online?

A: It takes few good cartons as standard, scans it using High Resolution CCD cameras, creates the template and inspects the other cartons for good and defected ones. The machine is offline type.

Q: What is the maximum speed of the machine?

A: 250 meters / min (Can vary depending on the job size)

Q: Do you have a Double Sheet sensor? If double sheet comes between the production what will happen?

A: Yes, it has Ultrasonic Double Sheet detector. If double sheets detect by sensor during production both cartons will be rejected.

Q: Can we adjust the tolerance level in different regions of the carton to enable differentiation between critical & Non-critical parameters?

A: Yes, we can adjust the tolerance level for every regions of the cartons depending upon QC requirements.

Q: Can we generate a Defect report (MIS REPORT) that can be downloaded to a USB for each job?

A. Yes, we can have a summary defect report for every job with defect images and other details.

Pictures At Glance:

![]()

![]()

![]()