Full Automation Carton Inspection Machine For Cigarettes Packaging Quality Control

Product Details:

| Place of Origin: | China |

| Brand Name: | FOCUSIGHT |

| Certification: | ISO9001/CE |

| Model Number: | FS-SHARK-500 Plus |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Plywood |

| Delivery Time: | 60 days |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 20 Machine/Month |

|

Detail Information |

|||

| Machine: | Full Automation For Cigrette Blanks | Maximum Size: | 500mm × 420mm |

|---|---|---|---|

| Minimum Size: | 90mm × 90mm | Speed: | 250m/min |

| Power: | 15KW | Paper Weight: | 90 ~ 400 GSM |

| Machine Mechanical Size: | 18000mm * 4100mm * 2500mm | ||

| Highlight: | quality inspection system,industrial inspection equipment |

||

Product Description

Focusight high speed full Automation for Cigarettes Packaging Inspection Line Model SHARK500-PLUS

FS-SHARK-500-PLUS

Cigarette Blank Automation Solution

Product Description

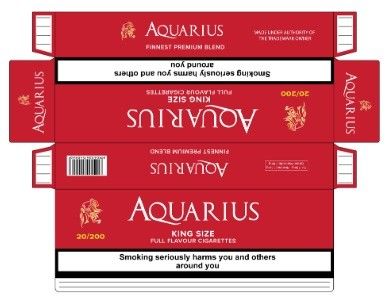

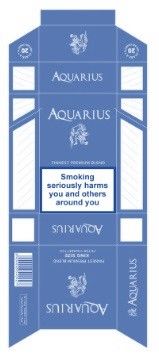

What: The Focusight Inspection Machine will precisely find out the defects of printing on presswork and reject the bad ones from the good ones automatically.

How: The Focusight cameras scan some good presswork as “STANDARD” and then while the rest of the printed jobs are inspected be scanned one by one and compared with the "STANDARD", any mal-printed or defective ones will be rejected automatically by the system. It detects every type of printing or finishing fault – color misregistration, color variations, hazing, misprints, defect in the text, spots, splashes, varnishing missing & misregistration, embossment missing & misregistration, laminating problems, die-cut problems, barcode problems, Holographic Stripe, cure & cast and many other printing problems.

Equipment Advantages

- Cigarette / pharmacy whole process defects checking, support Variable data inspection

- Whole line can work integrally also support working each machine separately

- Latest software, Automatic create template, easily study, more efficient

- Multi-spectral color measure with double reject collection bin to realize color sorting

- Highest speed 120000pieces / hour, two staff working, connection package, saves labor cost

- Auto binding machine connect inspection machine, also can working separate by manual loading

Technical Specification

- Inspection Speed 250m / min

- Inspection Area 90mm * 90mm – 500mm * 420mm * Products with 650mm / 800mm width can choose suitable platform

- Paper type White / gray cardboards, METPET Silver paper, Gold laser paper Support Installation of 5 cameras at front

Front Cameras Inspection options:

- Print quality Detection: Stripe, Ink spot, color variation, overprint, mis-printed

- Post print quality detect: varnish, lamination, cast & cure, embossing, die-cut, scratch, foil, holograms

- Variable data module: QR code, verification code data check, position and appearance defects

- High color accuracy module: Installation multi-channel German camera

- Reverse Camera: White / black CCD camera, dirty, mosquito spot, appearance defects

Additional options:

- Pre-auto feed unit – Pre-storage transmission paper, auto twist paper, auto equal gripping, auto feeding

- Multi collection unit – Color variation separate collection, big defects separate collection

- Auto binding unit – Accurate count, carton stacking, convenient package

Mechanical Appearance – 18000mm * 4100mm * 2500mm

Focusight Inside Images

![]()